Introduction:

Controlling the unwanted gas or water production in oil wells is crucial to increasing the volume and quantity of oil production. StimMax™ High Stability Foamer will produce a high volume, highly stable foam that is characterized by small uniform micro-bubbles. This product is specially formulated to create a seal in gas-producing zones, effectively trapping the gas and unwanted water and condensate. There is considerable interest in the application of foams in enhanced oil recovery processes involving miscible or immiscible gas displacement (CO2, hydrocarbon gases etc.). From a reservoir perspective, foams can provide a means to counteract the displacing agent's naturally high mobility and low density and will therefore reduce fingering (channeling) and gravity override. Foams can also be applied near-well to reduce gas coning.

In any reservoir application of foam there will come a point at which foams come into contact with residual oil. It has become common to hear that it is impossible to make foams that will be stable in the presence of crude oil…particularly, since oils such as Castor oil and even crude oils are among the earliest chemicals to be used for foam inhibition and foam breaking.

Solution:

StimMax™ High Stability Foamer employs a unique blend of readily biodegradable and sustainable ingredients that will provide high stability and non-corrosive performance. This product is specially formulated to create a seal in gas-producing zones, effectively trapping the gas and unwanted water. By producing a high quality foam capable of invading the gas zone and sealing it, StimMax™ High Stability Foamer stops the unwanted gas flow toward crude oil channels, making it particularly well suited for use in all types of wells as well as being effective in fresh water, brines, and any strength hydrochloric or sulfamic acids. The product is also effective in water contaminated with hydrocarbons as it will provide excellent performance even in the presence of high concentrations of polyvalent cations, such as calcium and magnesium. Since our foam can exhibit a high carrying capacity (viscosity), they can also be used for sand or scale clean-outs. It can also be injected into a reservoir for mobility control or for blocking and diverting.

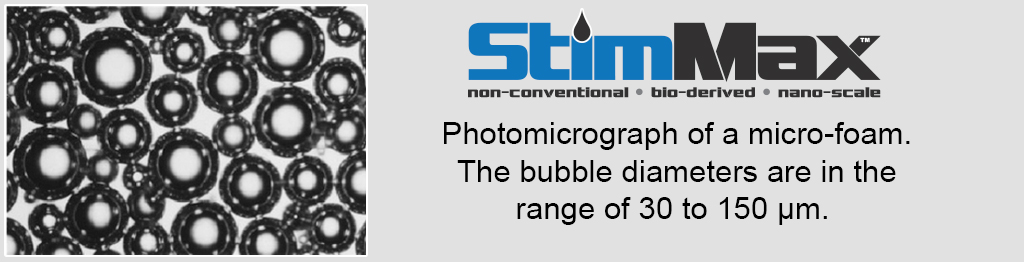

During a gas flooding process, injecting the gas with StimMax™ High Stability Foamer lowers the gas mobility and diverts at least some of the gas into parts of the reservoir formation that would otherwise remain unswept due to channeling or gravity override. Such diverting action produces increased oil recovery. Since foam mobility tends to be reduced disproportionately more in higher permeability zones, improvement in both vertical and horizontal sweep efficiency can be achieved. One essential property of StimMax™ Foamer is that it is stable in the presence of crude oil. Foams generated in a non-aqueous solution (kerosene) are typically washed out by crude oil flowing beneath the foam barrier. StimMax™ Foamers provide better foam stability with more rigid and longer lasting bubbles. StimMax™ High Stability Foamer can even improve microscopic displacement, by emulsifying oil into droplets that are small enough to permit their passage inside the foam’s lamellar structure, and thus contribute to incremental oil recovery.

Results:

StimMax™ High Stability Foamer is both an ecological way and economical way to seal and keep unwanted gas and water out of the way during production. StimMax™ has clearly shown that it is indeed possible to make foams that are oil resistant, or retain their native stability in the presence of crude oil, whether it is light or heavy crude oils. Additionally, these products can be used in foamed drilling and stimulation applications where the use of foam can improve the performance of the operation. Traditional foam systems that use CO2 foam for mobility-control purposes can create future corrosion problems because CO2 dissolved in an aqueous surfactant solution forms carbonic acid that is corrosive to steel tubulars. StimMax™ Foamer can also be used in enhanced oil recovery either as blocking and diverting agents to restrict unwanted flow or by improving the sweep characteristics of the mobile phase by reducing its mobility.